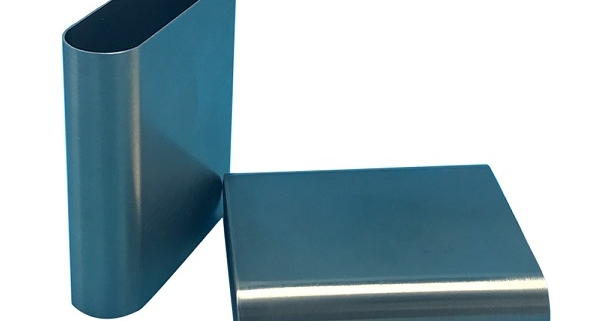

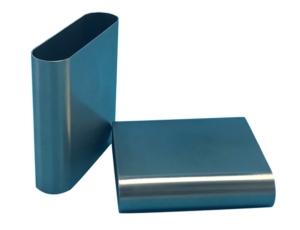

Aluminum deep drawing cans

Aluminum deep drawing cans

This Aluminum deep drawing cans is made by Aluminum 3003 .The surface is painting. It’s used for battery.It’s for our oversea customer and made according to their drawing.

- Material: Aluminum 1050 1060 1070 and so on

- Finish: custom

- Size:custom

Deep drawing services

Deep drawing is the process of stamping, pulling ring or metal die to deform the plate metal material into cylinder or box shaped parts. Deep drawing is usually carried out on the anti wrinkle pressing plate of the double action press, which can effectively prevent the raised edge from wrinkling when it is pulled into the steel mold.

Deep drawing Manufacturability

A. Raw Material

Copper ,BeCu, phosphor copper, Brass, Stainless steel, Aluminum, SGCC, SECC, steel, spring steel, Nickel-Silver… and all different kinds of metal;

B. SPEC

Roll material thickness is 0.05-10mm;sheet metal thickness is 0.3-20mm;

C. Surface treatment

Gold / Silver /Tin / Nickel / Zinc / Chromium / Copper-plating / Laser etching/Screen printing/Phosphating (can pass salt spray testing with 160 hours)/Black coating / Painting/ Power coating /Electrophoresis / Passivating /Deburring / Polishing / Brush according to ROHS standard;

D. Application

All different kinds of telecom products, Automotive, high-end digital cameras, Medical Equipment, Remote, Washing machines , vacuum cleaners, desk lamp, Furniture, Switch Power Supply, Socket, water heater, High-end toys, Calculator, Electrical, Interphone, Wireless Mouse, Wifi Router, Cordless telephone, mobile phone, Mobile DVD, Sounder. Auto Clutch, bicycle brake, scooter and so on ;

E. Quotation

Please provide the Formal drawings (normally, with DWG/STP/PDF file ),and make note with material/QTY/surface treatment and any other requirements, we will provide you the quotation sheet in 48-72 hours;

F. Prototype & Mould

We make the prototypes or moulds according to the drawings that confirmed by both of us and customers! The lead time is depends on the structure and qty of parts, Normally, lead time for prototypes is 3-15 days; lead time for mould is 10-25 days;

G. Production

We will provide samples according to the drawings to customers for approval. Then arrange the production and confirm the delivery date according to the Purchase Order; Normally , the lead time for production is 5-30 days ,the structure of parts is different , the lead time will be different .

H. Package

Plastic bags; Preserving Box; Reel/tape package; Plastic tray; Wood box; Export carton and any other customized package according to the customers’ requests.