Automotive Stamping

Automotive Stamping

At present, many manufacturing enterprises use the OEM model in their manufacturing sector, while they mainly control product design, development, sales and other fields. The most famous is the OEM between Apple and Foxconn. However, the traditional automobile industry still regards the manufacturing sector as the core competitiveness. There are still some differences among the manufacturing departments of different automobile enterprises, which correspondingly reflects the differences among different products. Generally speaking, automobiles are manufactured by stamping, welding, painting and assembly. Today we will briefly introduce the Automotive Stamping process.

Stamping production process is the process of stamping steel sheet into the body of automobile, that is, body panels and structural parts. Stamping is a traditional material forming process. With the development of automobile industry, stamping process is widely used in manufacturing industry. The stamping process greatly improves the accuracy and efficiency of material forming. Take the automobile industry as an example, stamping can punch one part every 5 seconds, and the accuracy of parts can generally reach more than 95%.

The development of stamping technology depends on the progress of die technology. Since the 1960s, the progress of computer technology and its application in manufacturing industry, computer aided systems such as CAD, CAE and CAM, the development and manufacturing efficiency of automobile die have been greatly improved. The machining accuracy of large 5-axis machining center has reached 0.01mm. Servo press has also brought great benefits and Convenienc to die debugging and parts forming.

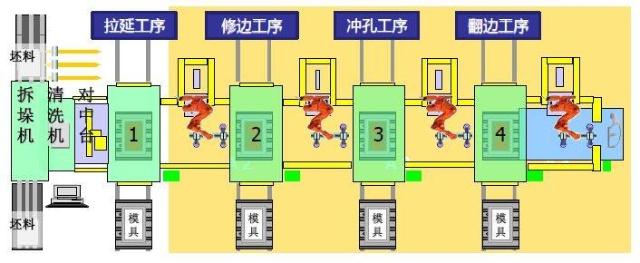

The stamping process of automobile parts generally includes four processes: drawing process, trimming process, punching process and flanging process. Each process corresponds to a set of moulds. Sometimes in order to save cost, a set of moulds is made for the following trimming and punching process, which is compressed into three processes. Drawing process is the main forming process. Through the drawing process, the main shape of the parts is basically formed. In addition, the parts after drawing can obtain certain strength and stiffness by deformation strengthening. The trimming process is mainly to remove the redundant auxiliary materials in the drawing process, such as drawing ribs, process supplementary surface, etc. Punching process, as its name implies, is to punch holes on parts. For some complex door inner plate dies, the punching process may need to punch more than 100 holes, which requires high accuracy and is difficult to process. Flanging process is mainly to turn the edges around the parts for later edge-wrapping process or subsequent assembly.

The stamping process of major automobile enterprises is basically similar, but the stamping technology of different materials is different. At present, under the background of automobile lightweight, more and more automobile enterprises adopt aluminium body. Due to the difference of material properties between aluminium and steel, there are some technical difficulties in stamping forming of aluminium body, and different surface treatments are needed in automobile die manufacturing.