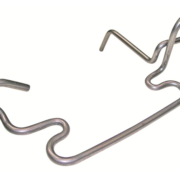

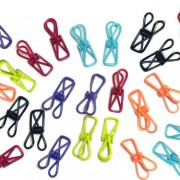

CNC Wire Forming Services

CNC Wire Forming

CNC Wire Forming Services Features:

1) With the largest wire diameter is 3.5mm.

2) Different shapes of hooks available

3) Normal ratio between wire diameter and inside diameter is 1: 2.5, and we have Successfully achieved 1: 1

4)Can design for your request

CNC Wire Forming Services

| Name | CNC Wire Forming Services Custom Wire Bending Parts |

| Equipments&facilities | CNC machine,Grinding machine,Stamping machines,punching machines,welding machine, cutting machine,bending

machine,electro-discharge machine, wire-EDM,lathing machine, trapping machine, automatic sand-blasting machine,laser engraving machine, hairline machine, automatic spray line etc. |

| Laboratory examine equipment | Coordinate measuring machine, XRF, Technical projector, Salt spray tester, HTHH test, Abrasion tester etc. |

| Quality control | Strict quality control system, including IQC,IPQC,FQC,OQC |

| Manufacture Process | Design moulds→ Confirm samples→ Purchase material→ Blanking→ Punching→ Welding/bending→ Forming→ Surface treatment→ 100% Inspection→ assemble products→ Package |

| Material | Spring steel,65Mn,60Si2Mn stainless steel 201,301,304,316,603 Brass,bronze,SECC,SPCC,aluminum,aluminum alloy, stainless steel, zinc alloy, nitinol,titaniumtim etc. |

| Surface treatment | Galvanize,Zinc,Nickel,Chrome plating, electrophoresis,painting,CNC milling, laser engraving& laser welding, sand-blasting, polishing, hairline brushing, spraying, anodizing, diamond cutting & high bright, printing, electro-deposition etc. |

Packaging & Delivery

Packaging Details: Polybag inside,Carton outside,or as your request

Wire Forming Services Custom Wire Shape Wire Bending Parts

Delivery Detail: 1-15 days,or as your request

Sample time of CNC Wire Forming Services

a) Pattern:30-45days after order

b) Sample:30days after pattern finishing.

c) The lead time is the general production period and does not include the transportation time.

New product development process of CNC Wire bending Services

Got tooling order and sample order with 50% deposit—Hold a meeting with the relation dept. to ensure the developing schedule—Design pattern, fixture and gauge and making them in our house—mold steel buying—Machining—Inspection—Send out the sample with initial inspection report.

Additional services

We are professional manufacturer,which mainly offer OEM / ODM service of Metal stamping parts,deep drawing parts,CNC machining parts,Wire forming parts.Our advanced equipments,professional engineers,high quality system,enable us to provide high quality with low production cost.Based on our strength, passion and capacity, we devote to supply one-stop service to customers.