Deep Drawing Sink Drains

Deep Drawing Sink Drains

Deep drawing sink drains are essential components used in kitchen and bathroom sinks to facilitate efficient water drainage. As a reputable manufacturer of metal stamping in China ,We aimed to provide OEM Drains at low cost and good quality. We do not sales them directly. Most products are designed by customer and cannot be sold.

1. Understanding Deep Drawing Sink Drains:

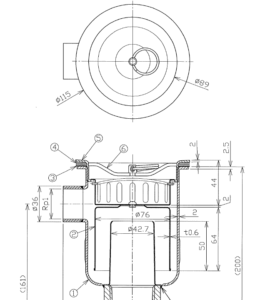

Sink drains are cylindrical or conical hollow structures that connect the sink basin to the plumbing system. They are designed to allow water to flow smoothly while preventing clogs and facilitating easy cleaning.

2. Manufacturing Process:

The manufacturing process of deep drawing sink drains involves several crucial steps, including material preparation, deep drawing, trimming, surface finishing, and quality control. Let’s explore each step in detail.

a. Material Preparation:

Sink drains are commonly made from stainless steel or other corrosion-resistant materials due to their durability and hygiene attributes. The selected material undergoes precision cutting and shaping to obtain a blank suitable for the deep drawing process.

b. Deep Drawing:

Deep drawing is the primary technique used to form the sink drain’s shape. It involves placing the blank material over a die and applying force gradually to draw the material into the desired shape using a punch. This process ensures the creation of a seamless, uniform, and strong sink drain structure.

c. Trimming:

After the deep drawing process, excess material is trimmed off to achieve the final dimensions and remove any irregularities. Trimming can be done using various techniques such as shearing, laser cutting, or machining.

d. Surface Finishing:

Sink drains undergo surface finishing treatments to enhance their appearance, improve resistance to corrosion, and facilitate easier cleaning. Techniques like polishing, plating, or electropolishing are employed to achieve desired surface properties.

e. Quality Control:

Stringent quality control measures are implemented throughout the manufacturing process to ensure that the sink drains meet the required specifications and standards. Inspections, measurements, and tests are conducted to verify dimensional accuracy, structural integrity, and overall performance.

3. Functional Advantages of Deep Drawing Sink Drains:

Sink drains offer several functional advantages, making them a preferred choice in the market:

a. Efficient Water Drainage:

The design of deep drawing sink drains allows for swift and efficient water drainage, reducing the risk of standing water and related issues such as bacterial growth or unpleasant odors.

b. Clog Prevention:

The smooth, seamless construction of deep drawn sink drains minimizes the chances of food particles, hair, or debris getting trapped, preventing clogs and ensuring uninterrupted flow.

c. Easy Cleaning:

The absence of seams and crevices in deep drawn sink drains makes them easy to clean. They can be quickly wiped down or rinsed without the need for specialized cleaning tools.

d. Durability and Longevity:

Deep drawn sink drains are manufactured from durable materials, ensuring long-lasting performance even under heavy usage. Their corrosion-resistant properties contribute to their extended lifespan and resistance to deterioration.

e. Aesthetic Appeal:

Sink drains manufactured through deep drawn stamping exhibit a sleek and visually appealing appearance, contributing to the overall aesthetic appeal of the sink and surrounding area.

Get a Quote

Please send us drawings or samples, we can quote you asap.After confirm quotation, we then start dies and productions according to your instructions.