Sheet Metal Fabrication

Our Sheet metal fabrication services focus on repetitive, low-to-high volume and high-mix production runs.The process include metal sheet bending, cutting, metal rolling,welding, pipe bending ,tube coiling and so on.Please send us drawing in 2D or 3D, we will send you free quotation within 24 hours

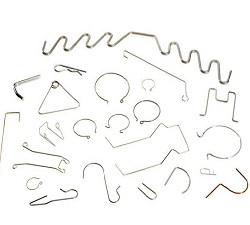

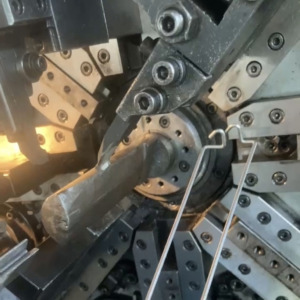

Wire Forming

We have many years of experience with Wire Forming with ability to support your needs from small to large sized runs with the highest quality and standards.Wire diameter from 0.1 mm to 12 mm. Cooperated with many material maker and can get a lot of different wires at small amount.Samples can be made in 1 days for the quickest situation.

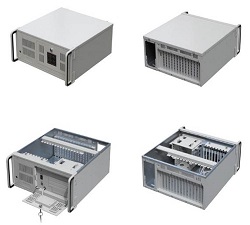

Deep Drawn Enclosures

As specialists in deep drawing and metal spinning technologies,We have been providing metal enclosures services for many industries.It’s subsidiary process of metal stamping and it’s our major production ability.We are in this field for more then 30 years and have full experiences for the deep drawing solutions. Many customer come to us due to our stable quality and strong technical support.

Prototyping

We are specialized in this field for many years with a strong management team and a technical product team,which supporting us to offer customer Rapid Prototype service perfectly.Just send us technical drawing, our team will thick over how to make your prototyping effectively and economically. Client enjoyed to do business with us.

Cost Effective Metal Stamping Solutions

We are china-based metal stamping parts manufacturing company providing world-class quality at China prices. We produce quality CNC machined parts, sheet metal fabricating, Deep Drawing,metal stamping prototypes and production, fiber laser cutting, tool and die making and related services.

We are china-based metal stamping parts manufacturing company providing world-class quality at China prices. We produce quality CNC machined parts, sheet metal fabricating, Deep Drawing,metal stamping prototypes and production, fiber laser cutting, tool and die making and related services.

We also have our own Stamping Die development, design and production plant. We passed ISO 9001:2008 quality management system certification and have been implementing the strictest quality control procedures during the production process to assure the products quality of each shipment of goods.We can handle large-sized products and high-capacity production…Read More

Why choose us?

- We offer a one shop stop for metal parts.

- Make the overseas communication easier.

- Cost effective to make sure most rational price.

- Quality control (ISO 9001-2008)

- Large company solutions with a small company “can-do” attitude.

- Innovative solutions for complex parts

- Complete logistic solutions.

Custom Wire Forms Manufacturer

Wire forms have limitless configuration options, making them commonly utilized in industrial and general consumer products. They are crafted from shaped wire and may incorporate parts found in lightbulb filaments, musical instruments, clocks, medical trays, pins, pegs, and rivets.

Choose from our selection of cotter pins, hitch pins, and custom wire forms crafted with precision and expertise. Our experienced team will work with you to identify the perfect material, size, and manufacturing process for your unique needs.

Offered in various wire sizes ranging from .006″ to 1.00″ and lengths up to 12′, our custom wire forms have numerous applications such as cotter pins, hitch pins, and lock pins, and also feature S hooks, D rings, figure 8 hooks, grip clips, hog rings, and more.

Our product boasts a wide range of configurations and sizes, and we also have numerous material options to suit your specific design and application needs. These include high-strength and annealed spring materials. We offer prototyping services and various coatings and surface treatments, such as plating, passivation, cleaning, polishing, and heat treatments. Additionally, we can provide custom packaging and JIT (Just In Time) delivery upon request. Our company holds ISO9001 certification and has extensive experience in industries such as aerospace, defense, agriculture, medical, and commercial, allowing us to guarantee top-notch performance for precision wire forms.

Precision Deep-drawing Manufacturer

Specializing in deep-drawing. Expertly crafted for a reason.

The deep-drawing process offers various benefits, such as resource conservation and enhanced properties, for metal items compared to other methods. This makes it a popular choice for manufacturers.

The deep-drawing process offers various benefits, such as resource conservation and enhanced properties, for metal items compared to other methods. This makes it a popular choice for manufacturers.

How does deep-drawing save resources?

- Deep-drawing reduces the amount of processing steps and thereby the labor.

The geometries of the items can often be created without requiring welds or additional finishing processes, resulting in a decrease in the overall number of operations. - Deep-drawing reduce energy consumption

Deep-drawn items differ from casted and forged items in that they do not require heating during processing, resulting in significant energy savings. - Deep-drawing reduces material waste

The items are crafted without creating metal shavings, resulting in a waste-free production process.

In addition, the high material strength of deep-drawn items often allows for the production of items using less material, while still maintaining quality.

The resource saving abilities of deep-drawing result in decreased unit-prices and reduced carbon footprint. This enhances customer profitability and CSR position.

Which abilities does deep-drawn items have?

- Deep-drawn items can be created, with fewer welds or even without

The product’s geometry can easily be created using a single sheet of metal rather than using multiple pieces that need to be welded together. This efficient method will achieve the desired geometry for the product. - Deep-drown items have smooth and homogeneous surfaces

Prevent irregularities on the surface of the material by eliminating gas bobbles and ash-marks, creating a smoother and more homogeneous finish. This enhances the overall appearance and quality of the product. - Deep-drawn items are strong

The cold metal forming process of deep-drawing does not produce small gas bubbles in the material, unlike hot forming processes. This lack of gas bubbles results in a stronger material due to reduced porosity.

The decreased amount of welds and smooth surfaces on deep-drawn items make them highly appealing for products where aesthetic appearance or ease of cleaning and disinfecting is crucial.

As an expert in our field, we regularly produce deep-drawn products for clients in the medical equipment, food processing equipment, and design industries. Our advanced manufacturing techniques cater to these specific industries, ensuring high quality and precision in our work.

Deep-drawn objects with high strength can greatly improve the durability and resistance of a product, while still maintaining a thin and high quality material. Our deep-drawing solution has been utilized by numerous customers looking to reduce costs and improve the manufacturing process of their existing products.

Which tasks can we solve using deep-drawing?

Deep-drawing is expertly performed for various industries including medical devices, food processing equipment, and automotive equipment.

We have the ability to shape various grades of sheet metal, including steel, stainless steel, copper, and titanium, ranging from 0.05 mm to 18 mm.

Our production line has the capacity to produce up to 90 punches per minute, utilizing anywhere from 40 to 1250 tons of pressure on both our hydraulic and mechanical press machines.

Utilizing deep drawing, roll forming, welding, surface treatment, turning, and milling, we are able to create a fully assembled and production-ready item. This process ensures efficiency and precision in the manufacturing process.

Our production facility is capable of handling both small and large quantities for companies of all sizes, providing a solution for various tasks.

Market We serve

Appliance

Automotive

Computer/Data Processing

Control Systems

Dental

Electrical

Electronics

Energy/Utilities

Medical

Office Equipment

Optical

Printing

Sporting Goods

Telecommunications

Toy & Games

Transportation

Equipment