Metal Spinning

Metal Spinning

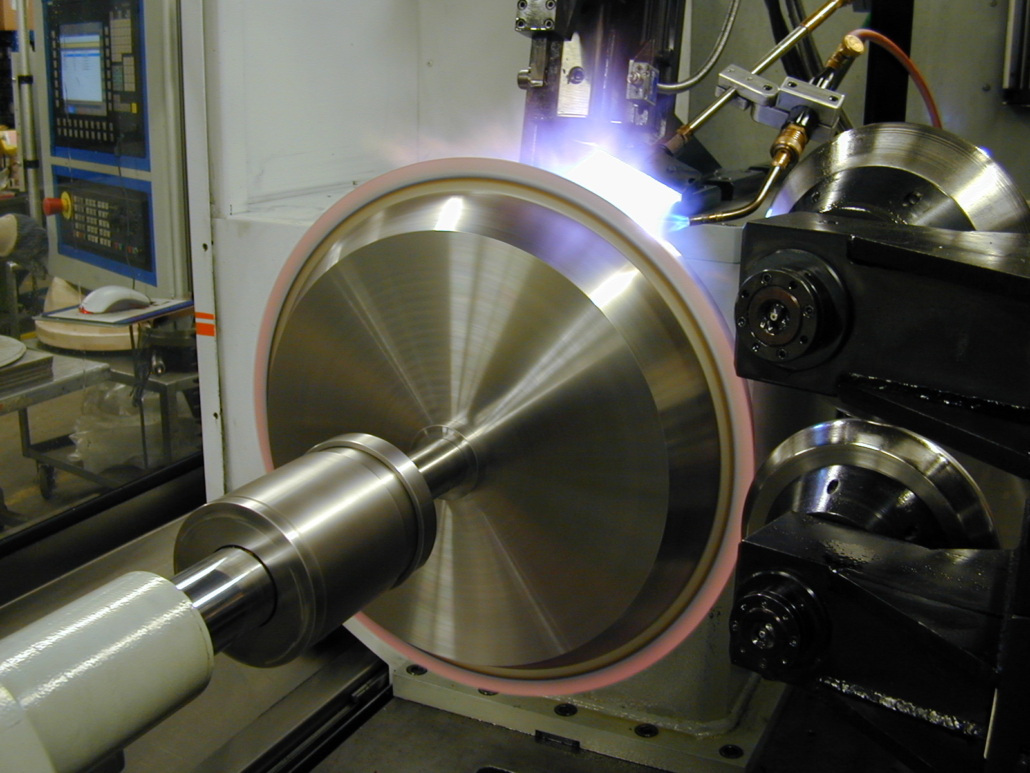

As a Manufacturer in China,we make Custom-made Metal spinning parts as above picture shows.Our team of skilled engineers excels in spinning techniques for diverse applications. Leveraging their expertise, they will collaborate with you to identify the most cost-efficient solutions, employing advanced CNC technology, tube spinning, panel spinning, or manual spinning methods. With the ability to work with a wide range of materials and sizes, we ensure seamless scalability—from prototyping to full-scale mass production.

What is Metal Spinning?

Metal spinning, also known as spin forming, is a metalworking technique utilized to transform a flat circular blank or disc-shaped workpiece into round shapes with axial symmetry. This process involves applying lateral force through a roller against the surface of the disc blank, while a high-speed spinning mandrel provides support and imparts the desired shape.

Unlike traditional methods that involve material removal, metal spinning enables the deformation of a circular metal sheet into diverse shapes. As the disc blank is shaped around the mandrel, it undergoes both tensile and compressive forces. The thickness of the original metal sheet may be intentionally reduced, depending on the spinning technique employed. Careful control of this reduction ensures the final product adheres to the specified requirements.

Metal spinning, an ancient technique that blends artistry and scientific principles, dates back to the era of the Egyptians and has undergone significant advancements over the centuries. Originally a manual process, it has now evolved into a sophisticated manufacturing method incorporating computer numeric control (CNC) technology.

Despite these advancements, manual metal spinning remains highly valuable in the production of precise and top-quality finished products. Mastery of this technique requires extensive apprenticeship and a distinct set of skills, emphasizing the artistic nature involved.

With its roots tracing back to ancient Egyptian pottery, metal spinning was inspired by the use of manually operated potter’s wheels as early as 3000 BC. Initially utilized for shaping wood and clay, metal spinning expanded to include the creation of circular iron shields by 25 BC.

During the Middle Ages, metal spinning gained prominence as a means to craft various items such as vases, tea kettles, and trophies. These objects were meticulously fashioned using wood spinning lathes with rotational drives, often powered manually by assistants. This historical context further highlights the enduring relevance of the metal spinning technique.

Please check more information about metal spinning on WIKI.

Metal Spinning Process

It’s a kind of process of Deep drawing.Fixed the flat blank or pre-formed blank to the rotating core die, applied pressure on the blank with a rotary wheel, and the rotary wheel was fed in axially at the same time. After one or more processing, various thin-walled hollow rotary products were obtained (see figure). It can be made of copper, iron, aluminium, stainless steel, titanium alloy and other plasticity materials.

When spinning, the contact area between the wheel and the blank is very small, the processing materials only have plastic deformation locally, and the resistance to deformation is small. Large-scale products can be processed with small-tonnage equipment. It is an effective method to manufacture hollow cones, cylindrical parts, hemispheres and thin-walled pipes and other precision products. Spinning products have high precision, good mechanical properties and wide size range. Spinning tools and dies are simple and easy to replace, and the cost of production is lower than that of other methods in manufacturing some products. The main shortcomings are long production time, low yield and limited varieties. It is suitable for the production of small batch, multi-variety products.

The new general spinning machine and the powerful spinning machine are driven by hydraulic pressure, and equipped with hydraulic profiling and numerical control system.

Small and medium spinning machine tools are mostly horizontal and large spinning machine tools are mostly vertical. Spinning machine tools require good stiffness, high power, high accuracy and good versatility. At present, the largest spinning machine can spin parts with a diameter of 6 meters, and the spinning wheel pressure is up to hundreds of tons.

Metal Spinning Manufacturer

Chinacustomstamping can work with a wide range of materials for metal spinning. We specialize in shaping all these materials using our metal spinning lathes and the capabilities of our deep drawing, stamping, and welding equipment. Our expertise allows us to craft your parts to your exact specifications within your budget. With over 20 years of experience in metal forming, we have applied spinning technology across diverse industries such as aerospace, automotive, military, ordnance, plastics, and lighting. Our team of engineers with specialized knowledge in metal spinning is available to assist you in designing custom parts and selecting the most suitable process to ensure the production of high-quality spun components at a competitive and affordable price. We also offer custom tooling to shape parts according to your specific configuration.

Find CNC Metal Spinning manufacturer in China

CNC and automatic spin forming machines produce components with precision that surpasses even the most skilled manual techniques. At Chinacustomstamping, we’ve integrated automated robots into our CNC production lines to further enhance accuracy and efficiency, particularly for large-scale orders, while delivering the fastest turnaround times. Our advanced robotic arms reduce cycle times by 18% during unloading tasks, ensuring flawless, defect-free products. Whether you need rapid prototyping or high-volume production, our versatile custom metal spinning services cater to a wide range of industries and applications, including:

- Agriculture

- Air Pollution & Ventilation

- Bearing Closures

- Commercial & Industrial Roofing

- Fireplace Accessories

- Flag-stand Bases

- Foodservice Lighting Fixtures

- Funeral Urns

- Industrial Vacuum Cleaners

- Marine

- Satellite Dish Manufacturing

Metal Spinning ability

Material range

The full range of material we can handle ,which enable us to offer best services to our customer

- Iron,

- Stainless Steel,

- Brass,

- Copper,

- Brozone,

- Aluminum,

- Steel,

- Carbon Steel etc.

Surface Treatment

The surface finish is very important part of products quality. We can do most common finish in current industry , such as

- Plating(Zinc plated, Nickel plated, Chrome plated,etc),

- polishing(precision can reach +/-0.005mm),

- knurling,

- anodizing,

- Black Oxide,

- heat treatment,

- sandblasting,

- powder coating, etc.

Thickness

From 0.5mm to 10mm thickness, or even 30mm, 50mm thickness. Our customer enjoyed the business with us. No matter small parts or huge parts ,we can offer our best solutions for you.

Technology

Customize CNC Sheet Metal Spinning Manufacturer From ChinaCNC spinning, precision cutting, direct precision, bending, drilling, tapping, stamping, drawing, CNC milling, laser cutting, welding and so on

Drawing

PDF, JPG, Auto CAD, E-Drawing, Pro/Engineer, etc

Accuracy Of Machining

The metal spinning accuracy is not so good as deep drawn stamping. According to our many years experience ,we can do +/-0.01 mm. Meanwhile, it depends on your item size.

Delivery time

Generally speaking, Sample 15~20 days, batch 20~25 days; Special items should be discussed

Application:

Application of lighting, inlet and exit, train fan, kitchen utensils, tableware, handicraft, machine accessories, agricultural harvester accessories, animal husbandry troughs, daily metal products, tubing fittings, machinery and other industries, etc.

Custom Spinning Services

In the past, metal spinning was limited to soft metals and small production runs, but modern advancements have transformed the process. Today’s cutting-edge metal spinning techniques enable high-volume production using the most durable materials available.

This evolution has made custom metal spinning an exceptionally cost-effective solution for creating rounded metal parts and products across a wide range of industries. At Metal Craft Spinning & Stamping, our hand and CNC lathe operations now support industries such as:

- Fast setup and quick changeovers for shorter lead times on new parts

- Affordable design modifications with minimal cost

- Enhanced tensile strength in the finished material

- Exceptional dimensional stability with tolerances as precise as thousandths of an inch or hundredths of a millimeter

- Improved grain structure for refined and strengthened materials

- High integrity and reliability for structural components

These capabilities make metal spinning a versatile and reliable choice for both prototyping and large-scale production.

As you know well from the above, we are professional manufacturer in China. If you need any of spinning products , please send us drawing or samples. We can quote you free at 24 hours .If any special and complicated items, we may need more time . However ,we can give you best production solution by our many years experience in this field.