Punching deformation process and section analysis

Punching deformation process and section analysis

Basic concepts of punching

Punching is a stamping process that uses a male and female die in a mold to separate a sheet of material. Generally speaking, punching mainly refers to the processes of blanking and punching. Blanking refers to cutting with a die along a closed contour curve, with the resulting part being the workpiece. Punching refers to using a die to make the part outside the closed contour curve as the punched part.

The blanking die is a mold used for separation processes such as blanking and punching. The working parts of the blanking die are different from the forming die, as it generally has a sharp cutting edge to shear the material, and the depth of the male die entering the female die is small to reduce wear on the cutting edge.

Punching deformation process

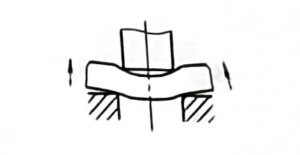

During punching, the deformation of the sheet metal has a distinct stage, transitioning from elastic deformation to plastic deformation, and finally resulting in fracture and separation

1.Elastic deformation stage

After the punch comes into contact with the sheet, pressure is applied, and the sheet undergoes elastic compression, stretching, bending, extrusion, and other deformations under the action of the punch and die. At this stage, the stress in the material reaches the elastic limit. At this point, the material under the punch is slightly bent, and the sheet on the die is upturned. The greater the gap between the punch and die, the greater the degree of bending and upturning. In this stage, once the punch is released, the sheet immediately returns to its original state

2.Plastic deformation stage

As the punch continues to press into the sheet, the pressure increases. When the stress state within the material satisfies the plastic condition, plastic deformation begins and enters the plastic deformation stage. As the depth of the punch into the sheet increases, the degree of plastic deformation increases, and the deformation zone material softens and the punching deformation resistance increases. Until the material near the side of the mouth begins to show micro-cracks due to tensile stress, the plastic deformation stage ends, and the punching deformation resistance reaches a maximum value.

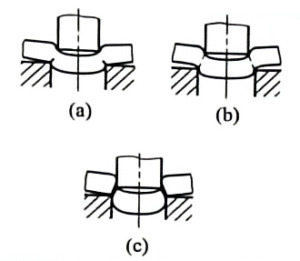

3.Stage of fracture and separation

As shown in Figures (a) to (c), the punch continues to press down, causing the stress in the deformation zone near the cutting edge to reach the material’s failure stress, resulting in cracks in the deformation zone on the side of the cutting edge of the male and female dies. The formed upper and lower cracks gradually expand and extend along the direction of maximum shear stress into the inner layer of the material until the two cracks meet, causing the sheet to be sheared and separated, ending the punching process.

Analysis of the section of the punched part

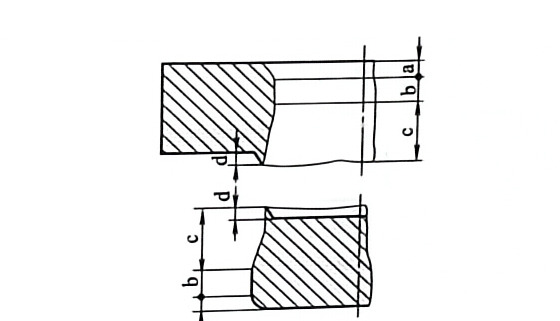

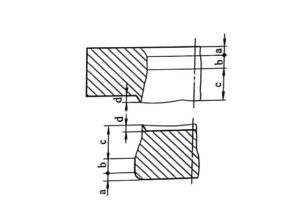

The section of the punched part can be divided into four distinct parts: the collapsed corner, the smooth surface (bright band), the rough surface (fracture band), and the burr, as shown in Figure 4-2

Figure 4-2 Analysis of the section of the punched part

a: collapse; b: smooth surface (bright zone); c: rough surface (fracture zone); d: burr

- 1.Collapse angle

Corner collapse, also known as fillet, is the result of material being dragged and deformed (bent and stretched) near the cutting edge during the punching process. The better the plasticity of the material, the greater the gap between the male and female dies, and the greater the corner collapse. - 2.Smooth surface (bright zone)

The smooth surface is also known as the shear surface. It is a bright, vertical section formed by extrusion of the material from the sides of the male and female molds when the blade cuts into the sheet metal and causes plastic deformation. The smooth surface is the most ideal punching section, and the dimensional accuracy of the punched part is measured by the size of the smooth surface. During ordinary punching, the width of the smooth surface accounts for about 1/3 to 1/2 of the thickness of the sheet metal. The better the plasticity of the material, the smoother the surface is. The rough and slightly inclined tear surface is formed by the main crack penetrating through. The wider the tear surface of a material with poor plasticity - 3.Muddy surface (fracture zone)

The fuzzed surface is a torn surface with a very rough and somewhat inclined surface formed by the penetration of the main crack. Materials with poor plasticity have a serious tendency to tear, and the proportion of fuzzed surfaces is also large - 4.Burr

Burrs are formed on the side near the cutting edge when micro-cracks appear in the material. As the punch continues to move downward, it elongates the formed burr and leaves it on the punched part. The smaller the cutting gap, the lower the burr height