Stamping Process Classification

Metal Stamping

We hereby wish to explain the Stamping Process Classification.First of all, we need to the details of stamping

Stamping is a forming processing method that relies on presses and dies to apply external force to plates, strips, pipes and profiles to cause plastic deformation or separation, so as to obtain the required shape and size of the workpiece (stamping).

Stamping Process Classification

Stamping is mainly classified by process, which can be divided into two categories: separation process and forming process.

The separation process is also called punching, and its purpose is to separate the stamping part from the sheet along a certain contour line while ensuring the quality requirements of the separated section.

The purpose of the forming process is to make the sheet metal plastically deform without breaking the billet to make a workpiece of the required shape and size. In actual production, multiple processes are often applied to one workpiece. Blanking, bending, shearing, stretching, bulging, spinning, and correction are the main stamping processes.

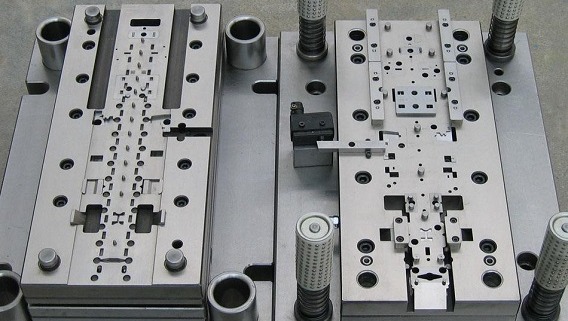

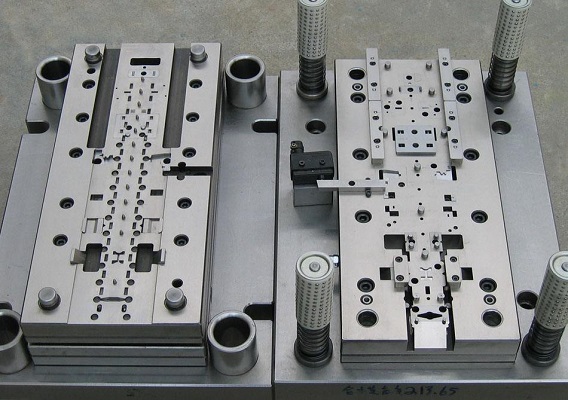

Blanking

Blanking is a basic stamping process that uses molds to separate materials. It can be directly made into flat parts or prepare blanks for other stamping processes such as bending, drawing, and forming. It can also be cut and trimmed on the formed stamping parts. . Blanking is widely used in industries such as automobiles, household appliances, electronics, instrumentation, machinery, railways, communications, chemicals, light industry, textiles, and aerospace. The blanking process accounts for about 50% to 60% of the entire stamping process.

Forming process

Bending

A plastic forming method that bends metal sheets, pipe fittings and profiles into a certain angle, curvature and shape. Bending is one of the main processes widely used in the production of stamping parts. The bending of metal materials is essentially an elastoplastic deformation process. After unloading, the workpiece will produce directional elastic recovery deformation, which is called springback. Springback affects the accuracy of the workpiece, which is the technical key that must be considered in the bending process.

Deep drawing

Deep drawing is also called drawing or calendering. It is a punching method that uses a die to make a flat blank after punching into an open hollow part. The deep-drawing process can be used to make cylindrical, stepped, tapered, spherical, box-shaped and other irregularly shaped thin-walled parts. If matched with other stamping forming processes, parts with extremely complex shapes can also be manufactured. In stamping production, there are many types of deep-drawn parts. Due to the different geometric characteristics, the location of the deformation zone, the nature of the deformation, the distribution of the deformation, and the stress state and distribution law of each part of the blank have considerable, even essential differences. Therefore, the method of determining the process parameters, the number of processes and the sequence, and the principles and methods of mold design are different. According to the characteristics of deformation mechanics, various deep-drawn parts can be divided into four types: straight wall revolution (cylindrical part), straight wall non-revolution (box-shaped body), curved revolution (curved part) and curved non-revolution. type.

Stretching

Stretching is to apply a tensile force to the sheet through the stretch die, which causes the sheet to produce uneven tensile stress and tensile strain, and then the mating surface of the sheet and the stretch die gradually expands until it fits completely with the stretch model surface. The applicable object of stretching is mainly to manufacture hyperbolic skins with a certain degree of plasticity, large surface area, gentle and smooth curvature changes, and high quality requirements (accurate shape, smooth streamline, stable quality). Because of the relatively simple process equipment and equipment used in the stretch forming, the cost is low and the flexibility is large; but the material utilization rate and productivity are low.

Spinning

Spinning is a metal turning process. During the processing, the blank is actively rotated with the spinning die or the spinning head actively rotates around the blank and the spinning die, and the spinning head feeds relative to the core mold and the blank, so that the blank is continuously and locally deformed to obtain the required hollow rotation Body parts.

Shaping

Shaping is the second trimming of the shape of the product using the predetermined shape of the abrasive tool. Mainly reflected in the pressure plane, spring foot, etc. Re-processing is used when some materials have elasticity and cannot guarantee the quality of one-time molding.

Bulging

Bulging is a processing method that uses a mold to stretch and thin the sheet and increase the local surface area to obtain parts. Commonly used are undulating forming, bulging of cylindrical (or tube) blanks, and stretch forming of flat blanks. Bulging can be achieved by different methods, such as rigid die bulging, rubber bulging and hydraulic bulging.

Flanging

Flanging is a plastic processing method that bends the material in the narrow band area of the edge of the sheet blank or the edge of the prefabricated hole on the blank into a vertical edge along a curve or a straight line. Flanging is mainly used to strengthen the edges of parts, remove trimming and make parts assembled and connected with other parts or three-dimensional parts with complex and specific shapes and reasonable spaces on the part, and at the same time improve the rigidity of the parts. When forming large-scale sheet metal, it can also be used as a means to control cracks or wrinkles. Therefore, it is widely used in industrial sectors such as automobiles, aviation, aerospace, electronics and household appliances.

Necking

Necking is a stamping method that reduces the diameter of the open end of the stretched flangeless hollow part or tube blank. Before and after the necking, the diameter of the end of the workpiece should not change too much, otherwise the end material will wrinkle due to severe compression and deformation. Therefore, it is often necessary to shrink the neck from a larger diameter to a smaller diameter multiple times.