Transfer stamping

Transfer stamping

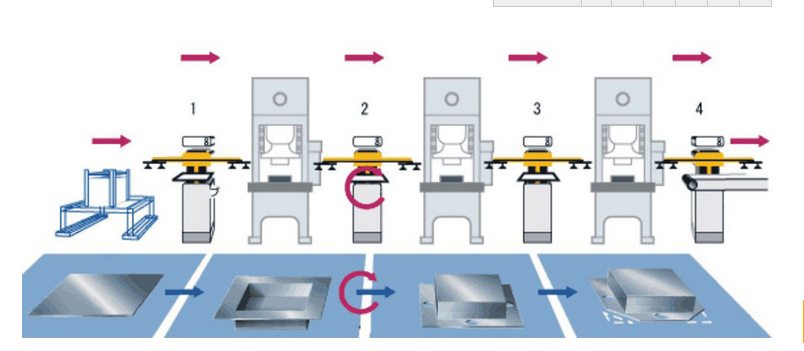

Transfer stamping is the integration of press, multi station die, rapid die change system, feeding system, feeding system, electrical control and network control system. Compared with single machine production or multi machine connection production, its biggest feature is that after completing one stamping, the press does not need to stop at the top dead center and wait for the feeding manipulator to transfer between stations, Instead, the press works continuously and the feeding manipulator transfers between stations at the same time, that is, it works in a continuous stroke instead of a single machine, which improves the production efficiency, reduces the failure rate of the equipment, reduces the use of operators and workplaces, and is conducive to reducing the comprehensive cost of stamping parts.

At present, there are two main forms of multi station stamping production line in China, namely single machine multi engineering stamping production line and two (three) dimensional stamping production line.

Single machine Transfer stamping production line

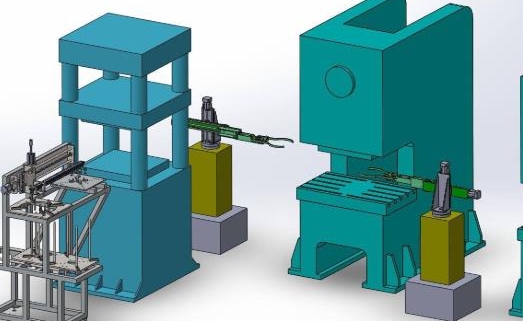

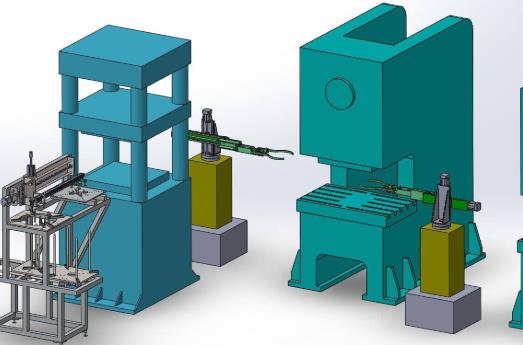

The single machine multi engineering stamping production line consists of an automatic production line, which is mainly composed of open two-point press, feeding system (coiler or sheet machine), single machine multi engineering manipulator, multi station die, etc.

The press in this production line is an open two-point press. The sliding block and worktable generally need to be customized and lengthened to put down the multi station die. The single machine multi engineering manipulator has two mechanisms: servo drive machine and intermediate station, which are respectively fixed to the ground. A cross bar is installed between the two mechanisms. The cross bar is equipped with an arm corresponding to the number of multi station molds, and the end of the arm is equipped with vacuum suction cup or electromagnetic suction cup.

During operation, during the empty stroke of continuous stamping of the press, the rotation angle of the crankshaft is detected by the encoder of the press and a signal is sent to the manipulator. The manipulator arm drops the specified stroke to absorb the material sheet → rise → transfer to the die in the X direction, fall → discharge → rise → return to the origin in the X direction, and repeat the above actions to make the production line produce continuously.

Due to the limited anti eccentric load capacity of the open two-point press, the size of the parts and the forming force of each station are small. The nominal force of the press is within 5MN, the weight of the parts generally does not exceed 3kg, and the production efficiency of the whole line is about 25 ~ 35 times / min. The main machine of this production line has the advantages of low cost, light manipulator structure, small cross-sectional area of clamping rod and low power of servo motor. It is suitable for multi station stamping production of small products.

Second (third) dimensional stamping production line

The second (third) dimensional stamping production line is mainly composed of closed double point press, feeding machine, manipulator, multi station die, etc.

The press in this automatic production line is a closed two-point press, which has the characteristics of large range of forming capacity and strong anti eccentric load capacity. The nominal force of the press is generally 6.3 ~ 20Mn. The manipulator adopts gantry mechanism. Two servo drives are installed on the left and right sides of the machine tool respectively. The two drives are equipped with two cross bars symmetrical to the front and rear directions of the mold. The cross bars are equipped with arms corresponding to the number of multi station molds. The end of the arms is equipped with vacuum suction cups or electro-magnetic suction cups. Among them, the three-dimensional manipulator is driven by two sets of servo motors more than the two-dimensional manipulator, The cross bar can move up and down.

The press in this automatic production line is a closed two-point press, which has the characteristics of large range of forming capacity and strong anti eccentric load capacity. The nominal force of the press is generally 6.3 ~ 20Mn. The manipulator adopts gantry mechanism. Two servo drives are installed on the left and right sides of the machine tool respectively. The two drives are equipped with two cross bars symmetrical to the front and rear directions of the mold. The cross bars are equipped with arms corresponding to the number of multi station molds. The end of the arms is equipped with vacuum suction cups or electro-magnetic suction cups. Among them, the three-dimensional manipulator is driven by two sets of servo motors more than the two-dimensional manipulator, The cross bar can move up and down.

Advantage and dis advantage of Transfer stamping

No matter which technical route is adopted, multi station stamping has higher production efficiency than conventional single station stamping, and in die design, because one stamping part is punched at a time, there is no problem of increasing production cost, and the process can be relatively dispersed to ensure the quality of stamping parts. It can also save manpower, plant land and semi-finished products transportation and storage area.

However, the die structure of multi station stamping is complex, the requirements of die manufacturing accuracy are high, the cycle is long, the cost is high, the maintenance is difficult, and the initial investment is large. Therefore, multi station stamping is generally used for mass production. In the process planning of new products, the stamping parts can be studied and compared with the traditional single machine single punch system in terms of process, tooling, equipment, cost, quality and production efficiency, and then decide whether to adopt and what kind of multi station stamping.