What is a forming die

What is a forming die

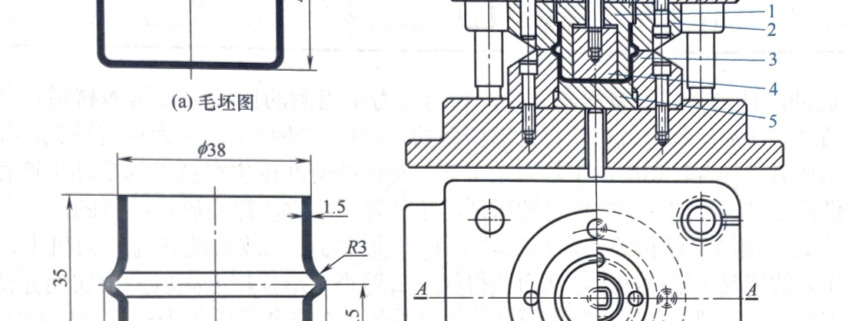

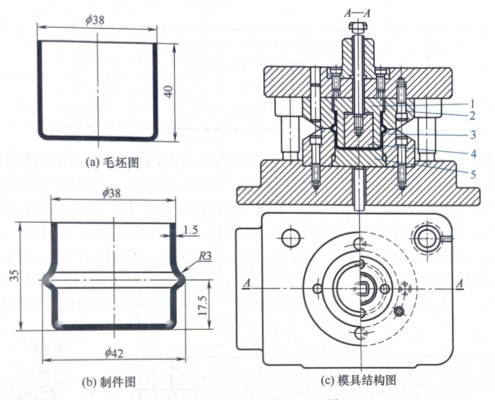

The mold that directly copies and forms the blank or semi-finished workpiece according to the shape of the convex and concave mold, and the material itself only produces local plastic deformation is called the forming die (as shown in Figure 1-5, it is the bulging die in the middle of the cylindrical part). The forming process can be divided into Burring, flanging, bulging, necking, expanding, undulating forming and sizing, as shown in table 1-4.It’s basic process for metal stamping and deep drawing.

Figure 1-5 bulging die

1-punch in the middle of cylindrical part; 2,3 – female die: 4 – unloader: 5 – Ejector

Table 1-4 Forming process

| Process | Sketch | Characteristics and application |

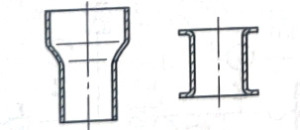

| Burring |  |

Punch the pre punched semi-finished sheet metal or the non punched sheet metal into a vertical edge |

| Flanging |  |

Shape the edges of semi-finished sheet metal into vertical edges according to curves or arcs |

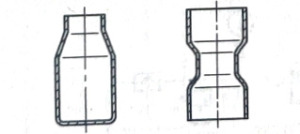

| Bulging |  |

Deformation is realized under the action of bidirectional tensile stress to form parts with various spatial surface shapes |

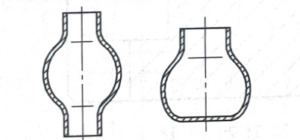

| Necking |  |

On a certain part of a hollow blank or tubular blank, its radial size is reduced |

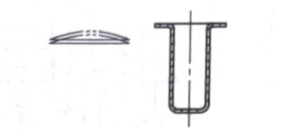

| Flaring |  |

On a certain part of a hollow blank or tubular blank, its radial size is expanded |

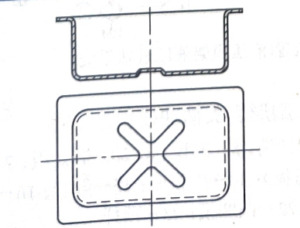

| Concave-Convex |  |

Bulges or depressions of various shapes are made on the surface of blank or workpiece by local forming |

| Shape correction |  |

Correct the manufacturing shape to improve the dimensional accuracy of the formed products or obtain a smaller fillet radius. |