Wire Forming & Custom Spring Solutions

ChinaCustomStamping has established itself as a premier manufacturer of precision wire forming and custom springs in China’s competitive manufacturing landscape. With over 20 years of specialized experience, we combine German engineering precision with China’s manufacturing efficiency to deliver exceptional quality components at competitive prices. Our ISO 9001:2015 certified facility houses state-of-the-art CNC equipment capable of producing complex wire forms and springs with tolerances as tight as ±0.005 inches (±0.127mm).

ChinaCustomStamping has established itself as a premier manufacturer of precision wire forming and custom springs in China’s competitive manufacturing landscape. With over 20 years of specialized experience, we combine German engineering precision with China’s manufacturing efficiency to deliver exceptional quality components at competitive prices. Our ISO 9001:2015 certified facility houses state-of-the-art CNC equipment capable of producing complex wire forms and springs with tolerances as tight as ±0.005 inches (±0.127mm).

What truly sets us apart is our commitment to providing complete manufacturing solutions – from initial design consultation through final delivery. We serve a global clientele across automotive, medical, electronics, and industrial sectors, with 80% of our production destined for international markets. Our integrated approach ensures consistent quality control at every production stage while maintaining lead times as short as 7 working days for standard orders.

Comprehensive Guide to Wire Forming

Introduction & Historical Background

Wire forming, an ancient manufacturing technique, traces its origins to the Bronze Age, where artisans crafted intricate gold jewelry. Over centuries, the craft evolved significantly, becoming pivotal during the Middle Ages and later integral to Industrial Revolution innovations. Today, it stands as a cornerstone of modern manufacturing, enabling the production of precision components across industries.

It is a manufacturing process that transforms straightened wire into custom lengths and shapes to meet the needs of various industries. Before shaping begins, the wire is first coiled and then straightened to ensure uniformity.

Due to their high malleability, wire forms can be easily bent, twisted, or shaped into intricate designs, making them suitable for a wide range of applications.

The wire forming utilizes different types of equipment, ranging from manual tools for precision handcrafting to semi-automated and fully automated machines for high-volume production.

Modern Wire Forming: Materials & Techniques

While traditional wire forming relied on simple round cross-sections, advancements in the 20th century introduced materials and methods to create trapezoidal, rectangular, and flat profiles. The process transforms metal wires—via bending, cutting, and shaping—into functional parts like springs, fasteners, and medical devices. Key materials include:

- Stainless Steels (304, 316, 434) for durability and corrosion resistance.

- Non-ferrous Metals like aluminum, brass, and copper for lightweight, conductive applications.

- Coated or Alloyed Wires (e.g., galvanized, beryllium copper) for specialized performance.

The Wire Forming Process: Step-by-Step

- Design & Material Selection

- Computer-Aided Design (CAD) specifies wire type, diameter, and gauge. Stainless steel or steel is chosen for strength; aluminum or copper suits lightweight needs.

- Straightening & Stretching

- Coiled wires are fed through rollers to remove deformities. Care is taken to avoid over-stretching, which can cause necking (thinning and weakening the wire).

- Shaping Through Applied Force

- Automated machines (e.g., CNC, hydraulic) or manual tools bend, twist, or cut the wire. Techniques include:

- Bending: Precisely forming angles or smooth curves in wire using mechanical force, typically through manual tools or automated CNC machines for consistent repeatability.

- Swaging: Reducing wire diameter or creating tapered shapes by compressing the material through dies, often used to form smooth transitions or prepare wire ends for assembly.

- Extrusion: Forcing wire through shaped dies to maintain exact cross-sectional dimensions along its entire length, ensuring uniform thickness and specialized profile requirements.

- Stamping/Twisting: Combining cutting/pressing operations with rotational forming to produce intricate patterns or interwoven multi-wire configurations for enhanced structural properties.

- Automated machines (e.g., CNC, hydraulic) or manual tools bend, twist, or cut the wire. Techniques include:

- Finishing

- Surfaces are polished, coated, or plated to enhance functionality. Processes like electro-polishing (removing surface layers for smoothness) or zinc plating (anti-corrosion) are applied based on the end use.

- Quality Assurance & Packaging

- Rigorous checks ensure compliance with industry standards, especially in critical sectors like healthcare. Sterilization, precise packaging, and tamper-proof sealing protect products during transit.

Wire Forming Methods

- CNC Wire Bending: Computer-controlled precision for prototypes or low-volume batches.

- Four-Slide Forming: High-speed, multi-tool stamping for mass production.

- Roll Forming: Cost-effective for creating threads, grooves, or hardened components.

- Coil Winding: Producing electrical components by wrapping wire around a core.

- Hydraulic/Pneumatic Systems: Automated shaping for consistent, high-volume output.

Applications & Industry Impact

Wire-formed products are ubiquitous, from automotive springs to medical implants. Innovations in automation and materials have expanded their role in packaging, electronics, and renewable energy. Quality-driven sectors, such as aerospace and healthcare, rely on stringent tolerances and biocompatible finishes to ensure safety and performance.

Material Options for Wire Forming

We maintain an extensive inventory of premium materials to meet diverse application requirements:

Stainless Steels:

- 302/304/316 – Austenitic grades for superior corrosion resistance in medical, marine, and food-grade applications.

- 17-7 PH – Precipitation-hardening stainless steel for high strength and fatigue resistance in aerospace components.

- 410/420 – Martensitic grades offering excellent wear resistance for cutting tools and industrial blades.

Spring Steels:

- Music wire (ASTM A228) – High-carbon steel with exceptional tensile strength for precision springs.

- Oil-tempered wire (ASTM A229) – Ideal for heavy-duty springs requiring durability and shock absorption.

- Chrome silicon (ASTM A401) – Heat-resistant alloy for high-stress applications like valve springs.

- Chrome vanadium (ASTM A231) – Superior fatigue resistance for automotive and machinery springs.

Copper Alloys:

- Beryllium copper (C17200) – High strength & conductivity, used in electrical contacts and connectors.

- Phosphor bronze (C51000) – Excellent elasticity and corrosion resistance for marine hardware.

- Brass (C26000) – Machinability and aesthetic appeal for decorative and mechanical parts.

Specialty Alloys:

- Inconel 600/718 – Nickel-chromium superalloys for extreme heat and chemical resistance (jet engines, nuclear reactors).

- Monel (400/500) – Nickel-copper alloy with outstanding seawater corrosion resistance.

- Titanium (Grade 1-5) – Biocompatible and lightweight, perfect for medical implants and aerospace.

- Nitinol – Shape memory alloy for medical stents and actuators requiring thermal responsiveness.

Advanced Wire Forming Technology

Our Advanced Manufacturing Process

At ChinaCustomStamping, we’ve perfected a comprehensive wire forming methodology that combines traditional craftsmanship with cutting-edge technology:

1. Computer-Aided Engineering

- 3D CAD modeling (SolidWorks, AutoCAD)

- CAM programming for CNC machines

- Finite element analysis (FEA) for stress simulation

- Tolerance stack-up analysis

2. Precision Fabrication

- 12-axis CNC wire forming machines

- Automated multi-stage bending systems

- Computer-controlled precision cutting

- In-line vision inspection systems

3. Quality Assurance

- First article inspection (FAI)

- Statistical process control (SPC)

- Material certification verification

- Functional testing protocols

Wire Forming Technical Capabilities

Our production facilities boast impressive specifications:

- Diameter Range: 0.1mm – 20mm

- Length Capacity: 1.5″ to 12 feet

- Tolerance Standards: ±0.005″ standard (±0.001″ achievable)

- Production Speed: Up to 1,200 parts/minute

- Bend Complexity: Up to 15 bends per component

- Surface Finish: Ra 0.2μm to 3.2μm

Custom Spring Manufacturing Expertise

Comprehensive Spring Solutions

In addition to wire forms, we specialize in producing high-performance springs for demanding applications:

Spring Types:

- Compression springs (standard, conical, barrel)

- Extension springs (various hook configurations)

- Torsion springs (single or double body)

- Wire forms with spring characteristics

- Custom wave springs and belleville washers

Material Options:

- High-carbon spring steels

- Stainless steel spring wire

- Nickel-based alloys

- Exotic materials per specification

Quality Standards:

- ISO 9001:2015 certified production

- SGS material certification

- ROHS/REACH compliance

- PPAP documentation available

Quality Assurance & Testing

Our Commitment to Excellence

We maintain rigorous quality control measures throughout production:

In-House Testing Laboratory:

- Metallurgical analysis (1000X magnification)

- Salt spray testing (ASTM B117)

- Mechanical testing (tensile, torsion, fatigue)

- Hardness testing (Rockwell, Vickers, Brinell)

- Dimensional verification (optical comparators, CMM)

Quality Certifications:

- ISO certified

- SGS audited facility

- ROHS/REACH compliant materials

- ITAR registered (for defense applications)

Process Controls:

- Statistical process control (SPC)

- Gauge repeatability and reproducibility (GR&R)

- Process capability studies (Cp/Cpk)

- First article inspection reports (FAIR)

Wire Forming Applications

Where Our Components Excel

Our precision wire forms and springs serve critical functions across multiple industries:

Automotive:

- Fuel injection components

- Seat belt mechanisms

- Transmission system parts

- Electrical connectors

Medical Devices:

- Surgical instruments

- Orthodontic archwires

- Implantable components

- Diagnostic equipment

Electronics:

- Connector pins

- Relay contacts

- Battery contacts

- EMI shielding elements

Industrial Equipment:

- Agricultural machinery

- Conveyor systems

- Heavy machinery

- Valve components

Consumer Products:

- Appliance mechanisms

- Furniture hardware

- Sporting goods

- Electronic enclosures

Value-Added Services

Beyond Standard Manufacturing

We offer comprehensive secondary services to provide complete solutions:

Surface Treatments:

- Electroplating (zinc, nickel, chrome)

- Electroless nickel plating

- Passivation and chromate conversion

- Powder coating (various colors/textures)

- Electropolishing (medical grade)

Heat Treatments:

- Stress relieving

- Tempering

- Annealing

- Hardening and case hardening

Additional Processing:

- Precision machining

- Welding (resistance, laser, TIG)

- Assembly and packaging

- Laser marking and engraving

Why Choose Our Wire Forming Service?

Our Competitive Advantages

Engineering Expertise:

- Dedicated R&D team with 20+ years experience

- Free DFM (Design for Manufacturability) analysis

- Prototype development in 3-5 days

- Tolerance optimization consulting

Manufacturing Capabilities:

- 50+ CNC machines in operation

- 15,000 sqm production facility

- 1M+ monthly production capacity

- Vertical integration for quality control

Customer Service:

- 24-hour quotation response

- Dedicated project managers

- English-speaking engineering support

- Transparent communication

Global Logistics:

- EXW, FOB, CIF terms available

- Licensed hazardous material shipping

- Customs documentation support

- Just-in-time delivery programs

Get Started With Your Wire Forming Project

Simple Ordering Process

- Submit Your Requirements:

- Send drawings (DXF, DWG, STEP formats)

- Provide samples for replication

- Share specifications and quantities

- Receive Engineering Feedback:

- DFM analysis within 24 hours

- Material recommendations

- Cost optimization suggestions

- Prototype Development:

- 3-5 day turnaround for prototypes

- Functional testing reports

- Design refinement if needed

- Production & Delivery:

- Standard 7-15 day lead time

- Quality documentation provided

- Flexible shipping options

Contact our engineering team today to discuss your wire form or custom spring requirements. We’re committed to delivering precision components that meet your exact specifications, on time and within budget. Request your free quotation within 24 hours by submitting your drawings or samples to our technical team.

ChinaCustomStamping is your trusted partner for high-quality wire forming and custom spring manufacturing in China.We offer high quality products at low cost and fast production time.

Popular Wire Forms & Wire Fasteners

cotter pins

Perfect for securely locking fasteners in place, cotter pins are a widely used type of wire form fastener in the aerospace, military, defense, and commercial industries. we provides a variety of cotter pins including stock, standard, and custom options.

Hitch pins

Hitch pins, offered in a diverse range of sizes, are commonly utilized in the automotive, agriculture, and power tool sectors.

D rings

D rings are among the most adaptable wire forms, manufactured from a range of metal wire thicknesses and employed across various industries. They are utilized in tie-down systems, pet collars, and whenever an anchor is required to secure a cord or rope in place.

S hooks

Often referred to as safety hooks, S hooks feature a distinctive S shape and are utilized in commercial and consumer settings to suspend items like cords, cables, and hoses. In industrial scenarios, S hooks are employed to maintain cables at a secure distance from work zones.

CNC Multiple Bend Wire Forms

If your wire form requires multiple bends, our CNC machining capabilities are up to the task. Additionally, we can assist in designing and prototyping your wire forms.

Available Specifications:

– Standard Diameters: 3/32″-1″

– Metric Diameters: 0.2mm -12mm

– Standard Lengths: 1/2″-144″

– Metric Lengths: 12.7mm-3567mm

– Materials: Low carbon steel, stainless steel, and exotic materials

Head welded wire Forms

We offer one-stop solution for your wire forms. The head can be welded or machining according to your request. We are not only professional for wire Forming, also we can do welding and CNC machining.

Available Specifications:

– Standard Diameters: 3/32″-1″

– Metric Diameters: 0.2mm -12mm

– Standard Lengths: 1/2″-144″

– Metric Lengths: 12.7mm-3567mm

– Materials: Low carbon steel, stainless steel, and exotic materials

Flat Wire Forms

Generally speaking,the wire is round. However, some projects or items need to be made in flat wire according to their special usage.We also offer wire forms at flat wire.

Available Specifications:

– Standard Size: Customized

– Standard Length: Customized

– Materials: Low carbon steel, stainless steel, and exotic materials

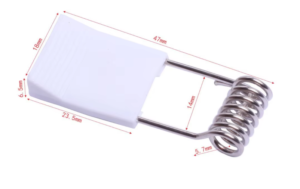

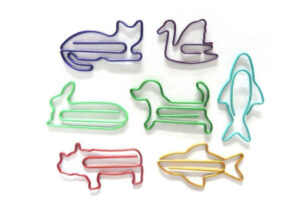

Wire Clips

There are numerous types of clips crafted from high-quality metal wire. In contrast to traditional options, these clips are available in diverse shapes and sizes, including animals, plants, and geometric figures.

Available Specifications:

Material:PET coated metal material ,Steel wire +rose gold /gold plated /painted /colorful plated .

Size:30-35mm or custom-design

Magnetic:Yes

Wire Diameter :1.0mm, 1.2mm ,1.5mm ,2.0mm, other diameter is available too.

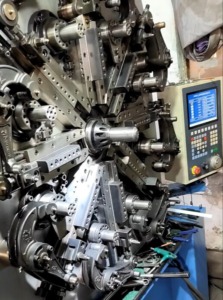

CNC Wire Bending & Wire Forming Machinery

Our facility is equipped with state-of-the-art automatic spring coiling machines and CNC spring forming systems, allowing us to consistently deliver premium-quality products with rapid turnaround times.

Factory View

As a trusted manufacturer serving global markets, we’ve built lasting partnerships with international clients by consistently delivering premium quality components at competitive prices.

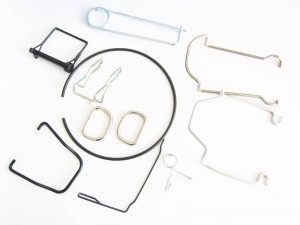

Wire Forming & Wire Bending Example

To understand our production ability clearly, we hereby wish to show some of our sample items .All wire forming items are custom-made according to customer’s sample or drawings. We do NOT sell them directly.

Please check more sample projects to know more about our wire forms or wire bending.

If you need a free quote for your new projects,please offer us following information.

- Material

- Finish

- Quantity

- Drawing with dimensions, or samples

- If possible, where it to be used. Maybe we have good suggestions

- Other details